Emulation for optimal structural design.

If you are fond to ancient world engineering and the surprising

achievements of the humanity such as the Pyramid of Egypt, you will

notice that the Pharaohs of the ancient empire had to perform some

failed attempts before they could build the Giza Pyramids Complex. After

the famous engineer, architect and erudite Imhotep built the stepped

Saqqara pyramid, of seventy meters high, the precedent Pharaohs

attempted the construction of next level pyramids.

But the next attempt, the Medium pyramid, ended up collapsing under its own weight, while the next one, the Dahshir pyramid, had to suddenly change its angle, since the collapse of its internal structure seemed to be unavoidable.

We had to wait until the Red Pyramid at short distance from the previous one, for achieving the adequate resting angle for obtaining the proper structural integrity.

Thousands of years later, during the XIX century when the railroad network extended to all the corners of the industrialized countries Great Britain and United States, as the leaders, the need of saving chasms and rivers, fomented the construction of bridges.

Not everybody was successful, Stirling, Broughton, Chester, Wooton, Tay in Scotland and Inerythan, were example of this delirious and tragic beginning of the structural engineering in the United Kingdom of the industrial revolution.

North America, also had its named failures, some already during the 20th century and several filmed as classic catastrophes movies.

All these structural failures that costed dozens of deaths and wounded helped as experience so we can now enjoy of safer structures, but not quite still.

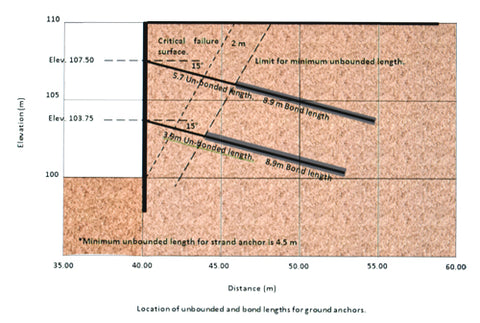

Even so this doesn't mean we no longer have structural failure. New needs present new challenges. The frail for urban space leads to the constriction of structures simultaneously higher and deeper, where the deep excavations incidents present themselves at an alarming rate.

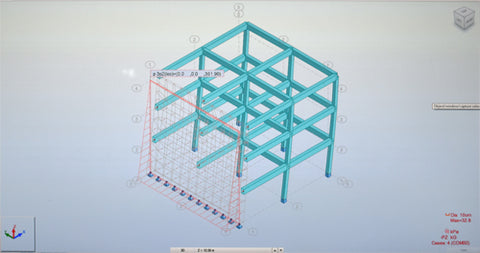

Here is where structural analysis software such as Autodesk Robot Structural permits us design structures and test them before wind or seismic load cases that may be catastrophic. Including big frames structures subjected to accidental loads.

This doesn't mean though that we should design thinking always on the catastrophes. Actually there's regulations and design codes regarding the cases that should be considered. The safety coefficients that should be respected and the accidental load cases that must be included.

In more practical cases, Autodesk RSA permits us to try different structural proposals without more work than changing the beams and columns section selection.

It's not unusual, that our first structural proposal happens to be somehow oversized. We all design with certain degree of fear that our design calculations present some error or that our sections cant bear the loads. Furthermore, that the design loads won't be respected and that the structure get overloaded. It's something rather common.

Autodesk Robot Structural allows us to observe the deformations in the structure in a graphic way before all the different load cases and combinations. The structure deforms affected by the a certain scale, so we can further appreciate each load effect.

From there we could verify the shear and bending moment graphs, but the most evident aspect is observing the deformations as we check each section.

With this information we can test different sections until we get to a solution that offer us the best relation between safety and economy.

It's easy to switch structural elements of steel or reinforced concrete and observe the deformations and critical points.

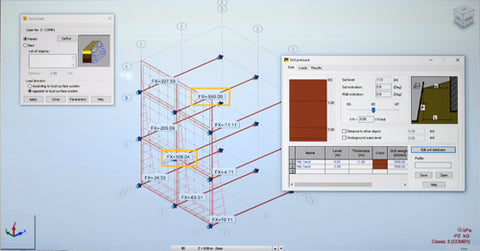

Before the same set of load cases combinations we can check different steel and concrete elements, observing the results through deformation that may be animated, but that will throw the results in a way of a color code and precise values over the deformation points.

Since we can determine the deformation scale, is quite easy to appreciate how the stresses are exerted over the structure.

From these first results and the real-time displayed safety coefficients it's possible to switch structural elements for slimmer or lighter members and observe the deformation and coefficient changes.

The simulation can be taken to a critical point and from there test members, connections or far more creative geometry elements that resolve the transfer of weight and stresses in a more clever way,so we can obtain lighter and more resistant structures.

As oppose to other calculation programs where the changes in the structure involves a long process of mathematical rethinking, in Autodesk Robot Structural such process is graphical making the analyst feel motivated to perform a bigger amount of changes y tests, as if it was some sort of virtual construction game.

The effects of each change in the structure are also displayed in a graphical way, being possible to work with complete combinations involving wind, seismic and accidental loads, including any other event to which the structure could be subjected along with its respective foundation.

But the next attempt, the Medium pyramid, ended up collapsing under its own weight, while the next one, the Dahshir pyramid, had to suddenly change its angle, since the collapse of its internal structure seemed to be unavoidable.

We had to wait until the Red Pyramid at short distance from the previous one, for achieving the adequate resting angle for obtaining the proper structural integrity.

Thousands of years later, during the XIX century when the railroad network extended to all the corners of the industrialized countries Great Britain and United States, as the leaders, the need of saving chasms and rivers, fomented the construction of bridges.

Not everybody was successful, Stirling, Broughton, Chester, Wooton, Tay in Scotland and Inerythan, were example of this delirious and tragic beginning of the structural engineering in the United Kingdom of the industrial revolution.

North America, also had its named failures, some already during the 20th century and several filmed as classic catastrophes movies.

All these structural failures that costed dozens of deaths and wounded helped as experience so we can now enjoy of safer structures, but not quite still.

Even so this doesn't mean we no longer have structural failure. New needs present new challenges. The frail for urban space leads to the constriction of structures simultaneously higher and deeper, where the deep excavations incidents present themselves at an alarming rate.

Here is where structural analysis software such as Autodesk Robot Structural permits us design structures and test them before wind or seismic load cases that may be catastrophic. Including big frames structures subjected to accidental loads.

This doesn't mean though that we should design thinking always on the catastrophes. Actually there's regulations and design codes regarding the cases that should be considered. The safety coefficients that should be respected and the accidental load cases that must be included.

In more practical cases, Autodesk RSA permits us to try different structural proposals without more work than changing the beams and columns section selection.

It's not unusual, that our first structural proposal happens to be somehow oversized. We all design with certain degree of fear that our design calculations present some error or that our sections cant bear the loads. Furthermore, that the design loads won't be respected and that the structure get overloaded. It's something rather common.

Autodesk Robot Structural allows us to observe the deformations in the structure in a graphic way before all the different load cases and combinations. The structure deforms affected by the a certain scale, so we can further appreciate each load effect.

From there we could verify the shear and bending moment graphs, but the most evident aspect is observing the deformations as we check each section.

With this information we can test different sections until we get to a solution that offer us the best relation between safety and economy.

It's easy to switch structural elements of steel or reinforced concrete and observe the deformations and critical points.

Before the same set of load cases combinations we can check different steel and concrete elements, observing the results through deformation that may be animated, but that will throw the results in a way of a color code and precise values over the deformation points.

Since we can determine the deformation scale, is quite easy to appreciate how the stresses are exerted over the structure.

From these first results and the real-time displayed safety coefficients it's possible to switch structural elements for slimmer or lighter members and observe the deformation and coefficient changes.

The simulation can be taken to a critical point and from there test members, connections or far more creative geometry elements that resolve the transfer of weight and stresses in a more clever way,so we can obtain lighter and more resistant structures.

As oppose to other calculation programs where the changes in the structure involves a long process of mathematical rethinking, in Autodesk Robot Structural such process is graphical making the analyst feel motivated to perform a bigger amount of changes y tests, as if it was some sort of virtual construction game.

The effects of each change in the structure are also displayed in a graphical way, being possible to work with complete combinations involving wind, seismic and accidental loads, including any other event to which the structure could be subjected along with its respective foundation.

published by Virginia E-Learning.